Holographic 3D Laser Printing

Sebastian Koch — Hector Fellow Martin Wegener

3D printing at the nanoscale is an established technology. However, for certain applications it is still considered prohibitively slow. Conventionally, laser beam pulses illuminate one volume element after another in a light-sensitive ink, building up the desired object. In this project, each laser pulse is holographically shaped and illuminates a large number of voxels in parallel. This technique promises orders of magnitude faster printing and shall be demonstrated for complex 3D structures.

Three-dimensional printing with resolution at the nanoscale offers numerous applications in various fields, such as photonics, biology and micro-robotics. One of the main challenges preventing an even more widespread use of this technology is to increase the often prohibitively low printing speed.

A leading approach is the solidification of a liquid ink by illumination with intense laser beam pulses, using two-photon absorption. Conventionally, a laser spot is scanned along the desired structure, assembling it sequentially from a large number of voxels, which are 3D volume elements in analogy to 2D pixels.

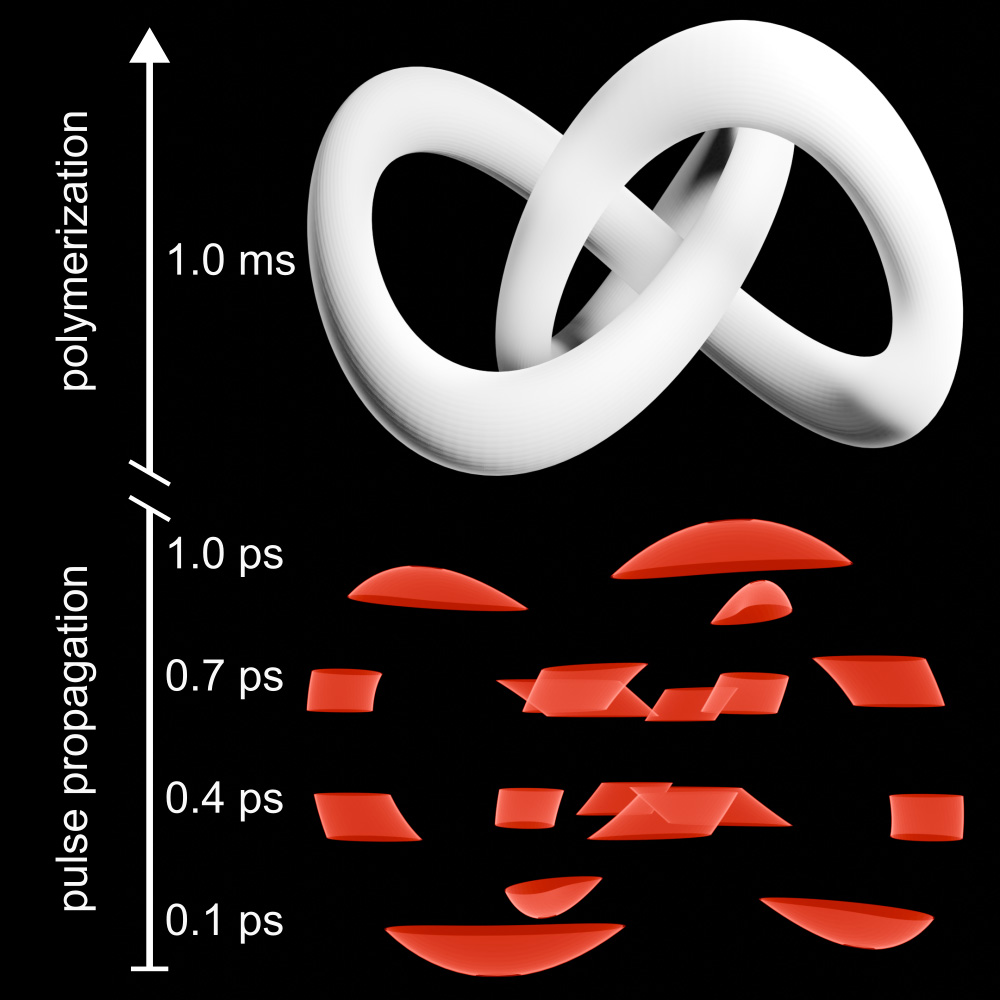

Holographic laser printing aims to increase printing rate drastically by illuminating a large volume, consisting of millions of voxels, in a single exposure. To this end, a carefully designed phase mask is used to shape the laser beam into a 3D hologram that resembles the desired structure. The required laser intensity is provided by an ultra-short laser pulse that appears spatially like a disk. As this “laser disk” propagates through the ink, the object is illuminated layer by layer, at the speed of light. These regions polymerise and form the final solid object, the other parts remain liquid and can be washed out.

In this project, the described printing technique shall be applied for complex 3D structures and the utility of different implementations of phase masks, such as diffractive optical elements, spatial-light-modulators and optical metasurfaces, is investigated.

A holographically shaped short laser pulse propagates through a light-sensitive ink, illuminating it. After a delay, the illuminated volume solidifies, producing the desired object.

Sebastian Koch

Karlsruher Institut für Technologie (KIT)Supervised by

Martin Wegener

Physics & Engineering