Design and Characterization of 3D-printed Microstructures using Deep Learning

Tim Alletzhäusser — Hector Fellow Martin Wegener

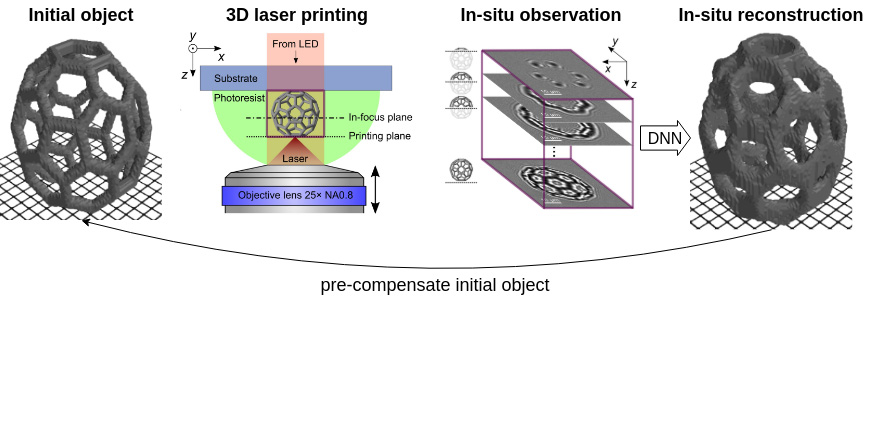

The project aims to accelerate and improve the fabrication of micromaterials by 3D laser printing through the use of deep neural networks (DNNs). Physical simulations of the printing process are developed and used to train the DNNs. They can then, for example, characterize the printed structures already in the printer or pre-compensate objects in such a way that iterative characterization and optimization outside the printer can be minimized.

3D laser printing is a versatile manufacturing approach for various optical elements or materials with special and extreme properties. A structure is printed by focusing a laser beam into a photoresist, which then polymerizes. Once printing is complete, the photoresist is removed with a solvent, leaving the printed structure behind. Subsequent characterization usually reveals that the printed object does not look exactly as it was designed. This is the starting point for a sometimes weeks-long optimization of the materials to obtain the desired structure after the process.

The topic of the doctorate is to simplify and accelerate this optimization process using various algorithms in the field of deep learning. The deep neural networks (DNNs) are trained to invert simulations based on physical equations, i.e. to calculate the initial state that led to a certain observation. The different DNNs can then be used to reconstruct objects during and/or after printing to reduce tedious characterization outside the printer. Furthermore, it will be investigated to what extent DNNs can be used to pre-compensate objects so that the desired object appears after printing, and optimization by the users is no longer necessary or at least minimized.

Optimization workflow of 3D laser-printed microstructures.

Tim Alletzhäusser

Karlsruher Institut für Technologie (KIT)Supervised by

Martin Wegener

Physics & Engineering